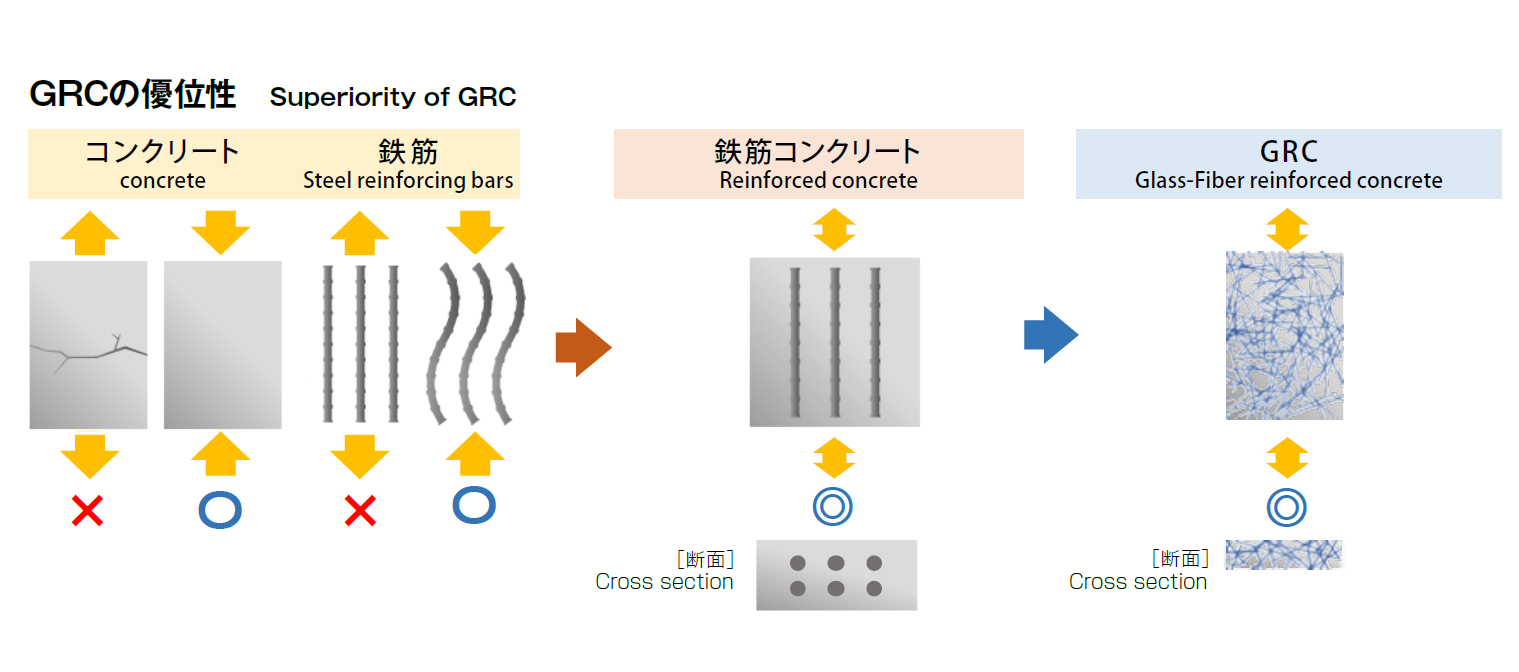

GRC is short for glass-fibre reinforced concrete, cement or cement mortar that has been reinforced with alkali-resistant glass fibres. It is a composite material made from inorganic cement, which is inferior in its tensile strength and toughness, and glass fibre, which complements wth it superior tensile qualities. Reinforcement with glass fibres allow concrete to retain its strength, whilst being highly designable, lightweight, and resistant to salt damage.